: Could not find asset snippets/file_domain.liquid/assets/img/top/loading.png)

焼物の肌はずっとみていても飽きることはない。見れば見るほど奥行きがあってその宇宙に魅了される。

斑唐津とは唐津焼の一種で、代表的なものは乳白色をした全体のなかに青や黒の斑紋が混じることから、斑(まだら)唐津と呼ばれている。この斑が作り出す偶然の表情は、オーロラとも虹色とも表現したくなる色気を醸していて、私は焼物を手にとりながら、この美しく不思議なテクスチャーを染色で表現できないだろうかと考えた。

沢山の資料と共に訪れたのは、京都で様々な染色に挑戦を続けている西田さんだった。

実際に自分が大切にしている矢野直人さんの斑唐津を持ち込んで、焼物の表面に現れた宇宙のようなテクスチャーを眺める。話し合う中で、様々なアイディアが出された。

焼物を作るように土を生地に塗ってみようか?柿渋を塗ったら赤土の様なテクスチャーになるのではないか?染色の枠を超えたイメージが膨らんだ。

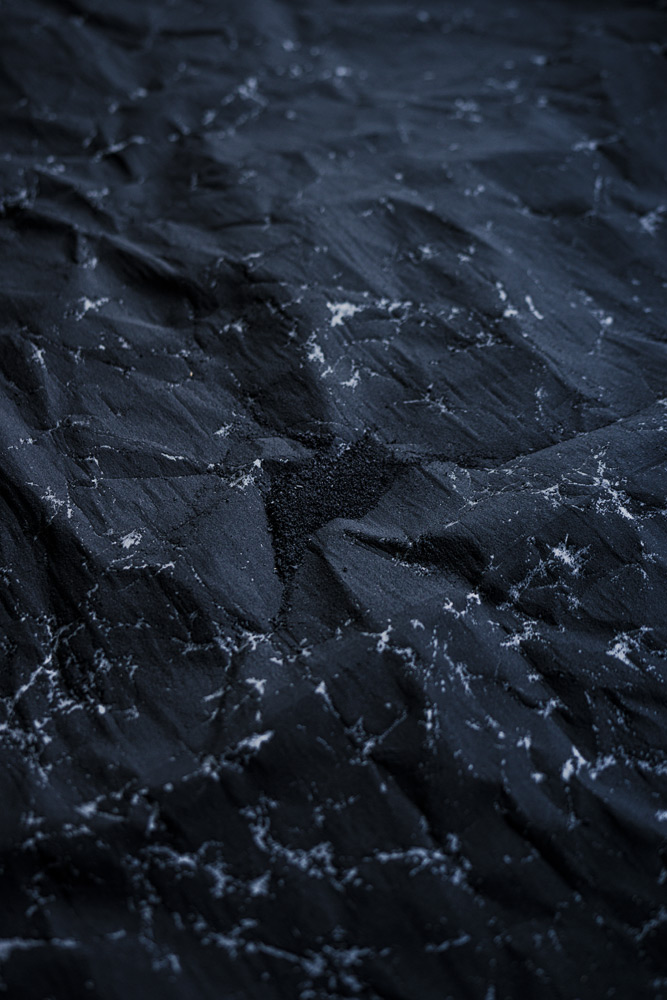

しかし一つ一つの可能性を試作しながら進めるもなかなか奥行きのある表情が生まれない。私がそれぞれの色のベースに求めたのが、焼物の肌に入った貫入と呼ばれる細かなひびだった。

そんな時に西田さんから出されたアイディアが、浴衣などで昔から使われてきたろうけつ染の技法を応用してお餅を生地に塗るというものだった。ろうけつ染は生地に蝋を塗ってそれを割り、そこに染料を染め込む技法だが、揮発系のもので洗い落とす必要があるそうだ。環境への負荷を抑えながらこの伝統的な技法を実現することができないかと考えてた時、お正月の鏡餅が時間と共にひびが入っていくのをみて、生地にお餅を塗ってみようと思いついたそうだ。

早速様々な試作がスタートした。

Looking at the surface of a ceramic piece, no matter how long you look at it, it never gets boring. The more you observe it, you get drawn into its beauty and depth, becoming captivated by its universe.

Madara Karatsu is a type of Karatsu ware, characterised by its milky surface interspersed with blue or black spots, hence the name ‘madara’ (meaning ‘spotty’ or ‘mottled’). The random patterns created by these spots exude a beauty that could be described as having the allure of an aurora or rainbow. While holding a piece, I wondered if I could express this beautiful and mysterious texture through dyeing techniques.

Accompanied with extensive research, I visited Mr. Nishida in Kyoto, who continuously explores various dyeing techniques. I observed the cosmic-like texture on a piece of Madara Karatsu by Naoto Yano, which I cherish myself, pondering how to express this onto garments. Through our discussion, we considered various ideas, such as applying clay to the fabric as if making ceramics, or using persimmon tannin to create a texture similar to red clay. Experimenting with these techniques, it was challenging to achieve the expression with depth I was satisfied with. I aimed to incorporate the intricate cracks known as ‘kannyu’ found on the surface of ceramics into the base colours.

While experimenting, Mr. Nishida proposed a technique inspired by traditional wax-resist dyeing used for yukata and other garments, it was to apply mochi (rice cake) to the fabric. Wax-resist dyeing involves applying wax to the fabric, cracking it, and then dyeing it, but it usually requires volatile substances to be washed off. While considering how to implement this traditional technique with reduced environmental impact, he recalled observing cracks forming on the mochi prepared for New Year’s, kagami mochi (mirror rice cakes) over time, and thus came up with the idea of applying mochi to the fabric. We soon started working on various prototypes.

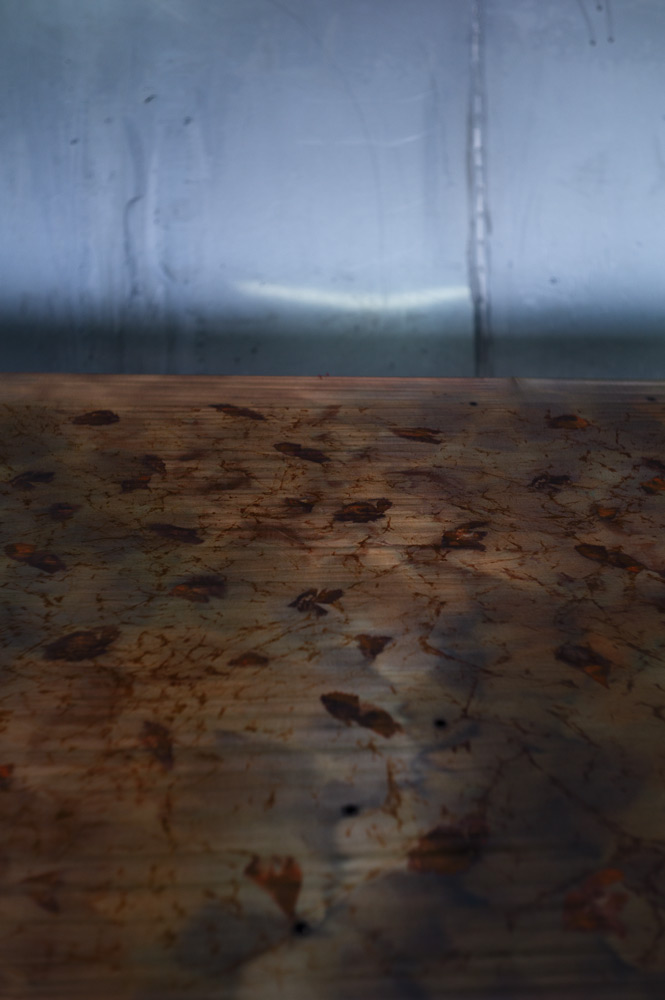

餅米をすりつぶしたものと墨を混ぜたものをシルクスクリーンで薄く、均等に擦っていく。餅米だけでは防染力がないものの、吸収力の高い墨を混ぜることで、染料も吸収するのだそう。そのため染めた後は真っ黒になる。西田さんが染料メーカーと何度も試行錯誤しながら最適な配合へ辿り着いた。炭の量が多すぎると染料を吸いすぎてしまうため、適量を見つけるのに苦労したそう。

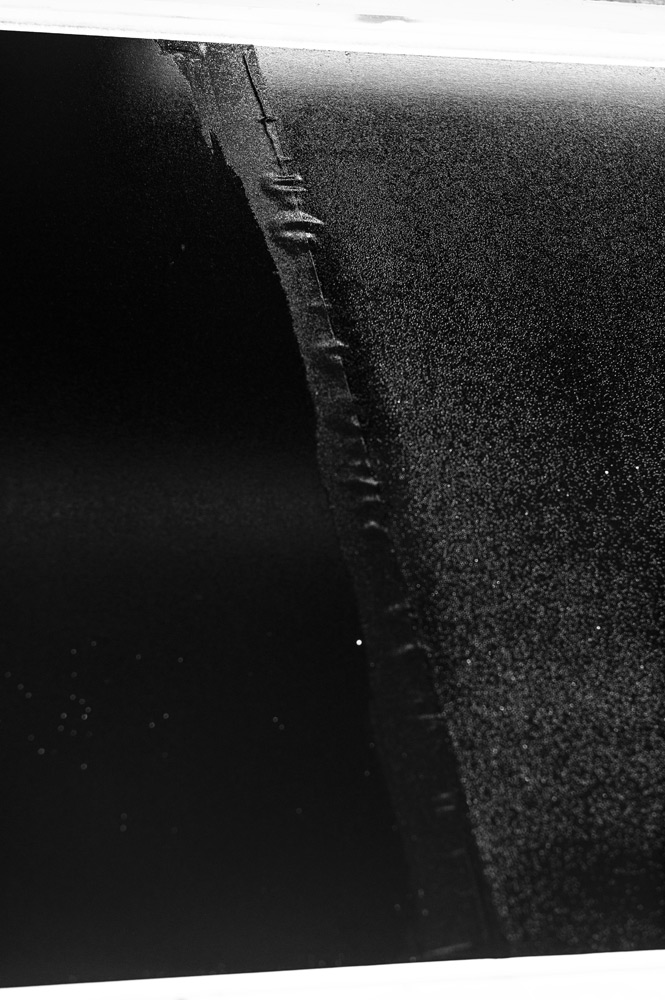

餅米を塗っては乾かし、それを3度続ける。そうするとシルクウールの生地には薄く黒い膜が重なってできるのだった。この層の厚さも試作ののちにベストな厚さにたどり着いた。自然乾燥とガス乾燥を繰り返し、しっかりと乾かしたら、今度はそれを手で割っていく。

生地を抱き抱えるようにまとめて、押さえつけて、丁寧にぱりぱり、ぱりぱりと音をさせて割りながらひびを入れていく。

生地全体に均一にひびが入ると、竹のロールがついた柱のような台に蛇腹状にかけ、その割れ目に刷毛で染料を塗り込んでいく。力を入れすぎると餅米が禿げてしまうので最新の注意を払いながら、刷毛で塗る回数と力加減を手の感覚で調整するそうだ。西日の入る工場には餅米割りと刷毛染めによって、細かな黒のパウダーが舞っていた。

A mixture of mashed mochi rice and ink is applied thinly and evenly using a silk screen. While the rice alone lacks the ability to resist dye, mixing it with the highly absorbent ink allows the dye to be absorbed as well. As a result, the fabric turns completely black after dyeing.

Mr. Nishida finally arrived at the optimal formulation after numerous trials with the dye manufacturer. Finding the right amount of charcoal was challenging, as too much would absorb too much dye. After finding the right balance, the process involved applying the mochi rice mixture and letting it dry, repeating the process three times. This process created a thin, black layer on the silk-wool fabric. Through experimentation, we determined the best thickness of the layer.

Once thoroughly dried through repeated natural and gas dying process, the fabric was then cracked by hand. As if embracing the fabric, it was gathered and pressed, carefully cracked with a crisp sound to create the intricate cracks.

When the fabric is evenly cracked, it is then draped in a pleated manner over a stand with bamboo rollers, resembling a column. The dye was then applied into the cracks with a brush. One had to be careful not to press too hard, as it could cause the rice to peel off, so the number of brush strokes and pressure were adjusted by hand. In the factory where the sunset streamed in, fine black powders from the rice cracking and brush dyeing danced in the air.

そうしてベースの染めが終わった生地を蒸して餅米を落とすと、それぞれの色の染色に入る。染色といっても通常の染色とは異なり全て絵のように染料を手で描いていく。目指したい陶器の肌理や質感のイメージを、私が生地幅の実寸大で描いた図案を元に、全てが職人の手描きだ。

ブラウンは唐津焼の肌の赤茶、釉薬から覗く火に焼かれた土を感じさせたかった。色を弾く防染のオレンジ色と3色の茶色を刷毛を叩くように、置くように、細かく刷毛を動かしていく。灰が飛んで生まれたほくろのような焼物の染みは、刷毛に染料を含ませて、とんとんとリズムカルに刷毛を揺らし、吹雪のように染料を飛ばしていく。

ブルーはオーロラの中を流れ星のように流れる斑唐津。ブラウンとブルーの染料を刷毛でしゅっしゅっと動きをつけながら描いていく。陶器の質感を出すため、ブルーの染料にオーロラの粒の様な樹脂を入れた。最終的には消えてなくなるが、光によって艶感が出て染料のムラ感に差が出る。釉薬が混ざり合うように染料と染料が溶け合い、色が混ざり合うことでオーロラの様な奥行きが生まれる。

染めと蒸し工程を2度繰り返し、私の依頼した生地はそれぞれ通常の染色工程の倍の時間がかかる。縦に長い工場に掛けられた生地は竹竿でぴんと張られている。この生地の貼り方も京都ならではの友禅染からきている。気が遠くなるほど、少しずつしか作業は進まない。 全て手描きで描かれた生地たちは、じわりじわりと染料が染み込み、乾いていくとまた色が変わっていく。その様子を呆然と眺めながら、こんなに贅沢な生地作りがあるだろうかと噛み締めていた。

一つの器が生まれるまでには果てしない道のりがかかる。山からやってきた岩たちを石臼で叩き、粉にして水簸し、ようやく粘土になったのちに形が生まれ、釉薬が重ねられ焼かれていく。この生地たちは、美しく滑らかな生地だが、着ることのできる焼物だと思う。

「かっこいいでしょう」と試作を繰り返すたびに、西田さんが言う。心から胸が踊るものづくりを一緒ができることを心から幸せだと思うのだった。

After the base dyeing is completed, the fabric is steamed, mochi rice is taken off and the process moves on to dyeing its colours. Unlike conventional dyeing methods, each dye is hand-painted onto the fabric, much like creating a painting. The texture and appearance of ceramics are carefully represented by hand of skilled artisans, using the designs I drew in its actual size.

For the brown hues, I wanted to evoke the reddish-brown texture of Karatsu ware and the feeling of clay fired in a kiln. Using an orange resists dye to repel colours and three shades of brown, the brush is tapped, placed delicately, and painted with fine brush movements. To express the freckles and stains found on ceramics created by ash, the dye is rhythmically dabbed and flicked with the brush, as if a snowstorm of dye occuring.

The blue represents the Madara Karatsu as if it were a shooting star flowing through the aurora. The blue and brown dyes are applied with the brush in a swift, flowing motion. To achieve the ceramic texture, resin resembling aurora particles are added to the blue dye. Although it eventually disappears, it creates a glossy effect under the light, adding variation to the dye’s unevenness.

As the dye’s blend together like glaze merging, the colours mix creating a depth similar to an aurora.

The dyeing and steaming process is repeated twice, a dyeing process that takes twice as long compared to the usual process. The fabric, which is stretched out in a long vertical factory, is tightly secured with bamboo poles. This method of stretching the fabric is inspired by the traditional Yuzen dyeing from Kyoto. The progress for the fabric takes time, requiring immense patience.

The fabric, hand-painted in its entirety, gradually absorbs the dye, and as it dries, the colours continuously change. As I watched this process in daze, I savored the thought of this luxurious approach to fabric making.

The journey to create a single ceramic piece is endless. Rocks from the mountains are pounded with a millstone, ground into a powder, and then water-weighed to finally form clay, which is then shaped, glazed and fired. Only then, does it take shape, be coated with glaze and undergo firing.

The fabrics are beautiful and smooth, but are wearable ceramics. Everytime we go through the prototypes, Mr. Nishida says ‘Isn’t it cool?’ I am truly grateful to be able to collaborate on such heart-stirring craftsmanship.